Cement mixed sand and gravel (CSG) dam / セメント混入砂礫(CSG)ダム

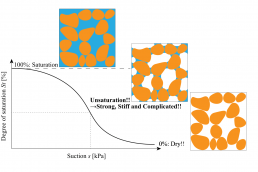

Cement mixed sand and gravel (CSG) dam is a newly developed technology by Japanese in recent year. Due to its significance in construction method and design, CSG dam has the advantages of low construction cost, environmental protection and site material utilization. However, it also classifies as a material in between concrete and geomaterial due to its low cement content and varied soil gradation. In this research, from the view point of geotechnical, the simple form of CSG material is investigated in terms of monotonic loading and viscous properties with comparison of four different cases: saturated sand, dry sand, dry sand with cement and cement mixed sand – simple form of CSG.

セメント混入砂礫材料(CSG材料(Cement mixed sand and gravel))を使用したCSGダムは,近年,日本で開発された新たな施工法である.その施工法や設計法のため,コスト,環境影響,現地発生土利用から,CSGダムは有効的である.また, CSG材料は,その低セメント比と粒形分布からコンクリートと地盤材料の中間に分類される.本研究では,地盤工学的な観点から,CSG材料の基本的な状態(飽和砂,乾燥砂,セメント混入乾燥砂,セメント混入砂)に関して,単調載荷特性および粘性特性を検討する.

Figure 1. Image of CSG dam

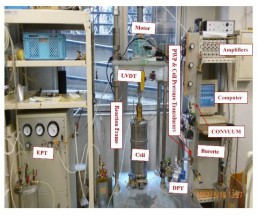

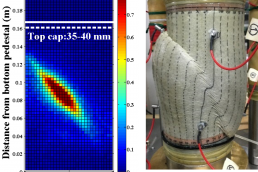

Figure 2. High Confining Pressure Triaxial Test

Monotonic Loading / 単調載荷挙動

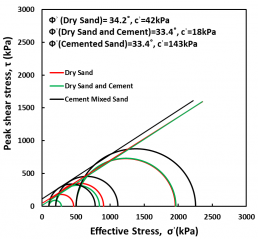

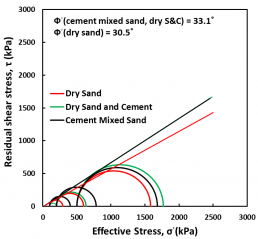

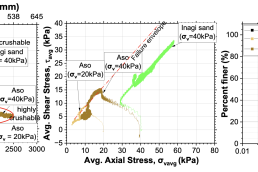

As for monotonic loading, at peak stress state, the effect of cementation is shown clear in the figure since there is an increment in stress. For residual stage, after reaching the peak stress stage, the specimen goes to residual stage and cement mixed sand and dry sand with cement cases are showing the same result, which indicates that the sand and cement are no longer binding with each other anymore at the shear band.

単調載荷試験結果(図1)から,セメンテーションの影響がピーク強度に表れていることが分かる.また,セメント混入砂とセメント混入乾燥砂の残留状態は同じであったことから,せん断帯形成に関しては,砂とセメントの相互作用の影響は少ないと考えられる.

Figure 3. Peak stress state

Figure 4. Residual stage

Viscous properties / 粘性特性

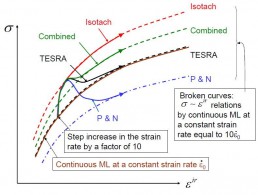

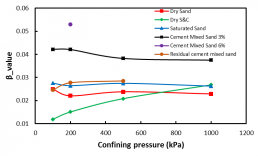

As for viscous properties, by changing the strain rate level 10 times at different axial strain, the β_value is summarized in the figure. It can be observed the cementation effect on the increase of β_value. Hence, the higher β_value, the more attention to be paid to creep deformation.

粘性特性を検証するため,載荷中にひずみ速度を10倍に変えた試験を行い,粘性特性を表すパラメータβで整理を行った.図より,セメンテーションによってβが増加していることが分かる.βが大きな材料ほど,クリープ変形に注意する必要がある.