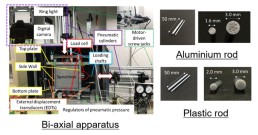

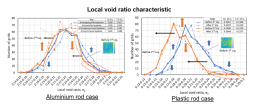

By taking into account the importance of local void ratio characteristics on liquefaction phenomenon, the bi-axial tests on assembly of aluminium rods and plastic rods were conducted along with the application of image analysis to visualize the change of local void ratio in the entire testing process without disturbance to the specimen. Both physical liquefaction behaviors and mechanical behaviors in terms of local void ratio of two types of rods can simultaneously be unveiled.

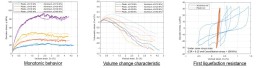

The global behaviors of two types of rod assemblies demonstrate both similarities and differences in monotonic and cyclic loading tests. For monotonic behaviors, the strengths are quite similar in both two cases, while the volume change characteristics, compressibility and swelling behaviors are different. As a result, Plastic sample has a higher liquefaction resistance under the same stress state condition.

In constant-volume cyclic loading tests, both types of rods show the same tendency against the liquefaction and re-liquefaction. The increase of liquefaction resistance from the 1st to 2nd liquefaction stage can be observed and confirmed. Also, the densification and homogenization are quantified in terms of local void ratio with the clear evidences.